Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

In today's world, where electrical devices are integral to our daily lives, the safety and efficiency of our electrical systems are paramount. Overloading power sockets and plugs can advance to dangerous situations, including electrical fires and damage to appliances. Understanding the importance of proper usage and the types of connectors available is crucial for ensuring a safe environment. This article will explore how to prevent overloading and highlight some key components, including the 24 pin industrial connector, electrical watertight connectors, and industrial cord connectors.

Understanding Electrical Overload

An electrical overload occurs when a circuit carries more current than it is designed to handle. This can happen when too many devices are plugged into a single socket, pilot to overheating and potential hazards. Signs of overload include flickering lights, warm or hot plugs, and tripped circuit breakers. To prevent these issues, it's important to adhere to a few basic guidelines.

Distributing Electrical Load

One of the more effective ways to prevent overloading is to distribute the electrical load across multiple outlets. Instead of using a single power strip for several devices, spread them out across different sockets. This reduces the risk of any single socket being overloaded and allows for more even distribution of electricity throughout your home or workspace.

In industrial settings, where high-powered equipment is common, using a 24 pin industrial connector can provide a reliable solution for power distribution. These connectors are designed to handle multiple connections, ensuring that power is effectively managed without overloading individual circuits. By using appropriate connectors, businesses can safeguard their electrical systems while increasing efficiency.

Choosing the Right Connectors

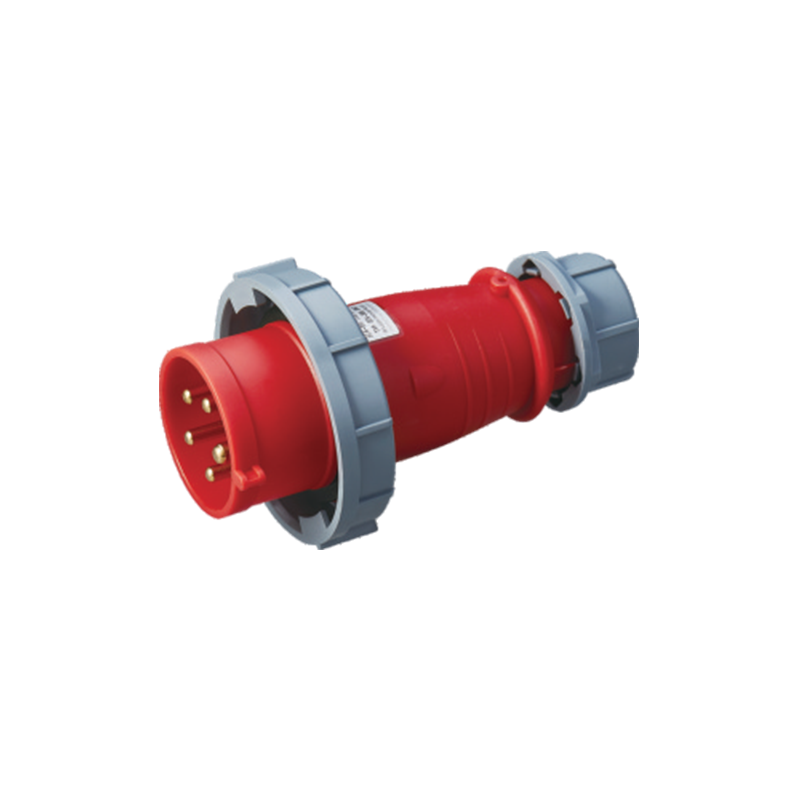

Selecting the appropriate connectors for your electrical needs is crucial in preventing overloads. For example, electrical watertight connectors are designed to withstand moisture and dust, making them ideal for outdoor applications or environments prone to spills. These connectors not only provide a secure electrical connection but also help protect against short circuits that could advance to overloading.

In industrial applications, the use of industrial cord connectors is vital. These connectors are built to endure harsh conditions and facilitate safe and reliable connections between power sources and equipment. Ensuring that the connectors used can handle the required load is essential in preventing overloading and potential equipment damage.

Regular Maintenance and Inspection

Regular maintenance and inspection of electrical systems play a significant role in preventing overloads. Inspect power cords, plugs, and sockets for signs of wear and tear, such as fraying or discoloration. If any components appear damaged, they should be replaced immediately. Moreover, periodic testing of electrical systems can identify potential issues before they escalate into serious problems.

Additionally, ensuring that connections are secure can help prevent arcing, which can cause overheating. For industrial applications, utilizing connectors like the 24 pin industrial connector allows for secure connections that lessen the risk of loose fittings, which could advance to overload situations.

Understanding Device Power Requirements

Another crucial factor in preventing overloads is understanding the power requirements of your devices. Each electrical device has a specific wattage rating, which indicates how much power it requires to function correctly. When planning your electrical usage, consider the cumulative wattage of all devices plugged into a single outlet.

For example, if multiple high-wattage devices are used simultaneously, the total wattage can exceed the socket's capacity. It's advisable to use devices with lower wattage or to stagger their usage to prevent overload. In industrial settings, this consideration becomes even more critical, as large machines often require substantial power. Properly utilizing connectors, such as electrical watertight connectors and industrial cord connectors, can help manage this demand effectively.

Educating Users

Lastly, educating users about the risks of electrical overload is essential. Many people are unaware of the dangers associated with overloading sockets and plugs. Providing training or resources that explain safe usage practices can significantly reduce the risk of accidents. Encouraging users to be mindful of the devices they connect and to respect the limits of their electrical systems is key.

Preventing the overloading of power sockets and plugs requires a multi-faceted approach that includes proper load distribution, selecting the right connectors, regular maintenance, understanding device power requirements, and educating users. By implementing these strategies, individuals and businesses can create a safer electrical environment. Utilizing components like the 24 pin industrial connector, electrical watertight connectors, and industrial cord connectors can enhance the safety and efficiency of electrical systems, lessen the risk of overload, and ensure reliable operation.