Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

In today's rapidly evolving technological landscape, electrical safety remains a paramount concern for both manufacturers and consumers. With the increasing reliance on electrical devices and systems, the design of plugs and sockets has taken center stage in ensuring safe operations. This article explores how effective plug design contributes to electrical safety, particularly through features like waterproof industrial sockets and outdoor power supply boxes.

The importance of plug design extends beyond mere functionality. A well-designed plug must provide a secure connection to a socket while also preventing accidental disconnection, which can advance to hazardous situations. The physical characteristics of plugs, including their shape, size, and the materials used, play a crucial role in their safety performance. For instance, a plug that fits snugly into its socket reduces the risk of electrical arcing and overheating, which can cause fires.

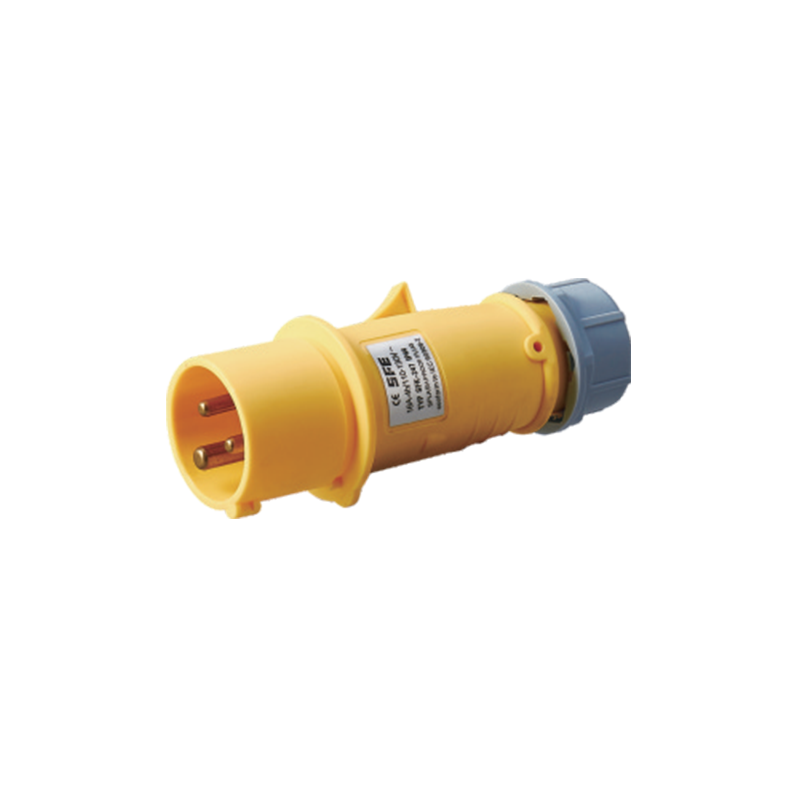

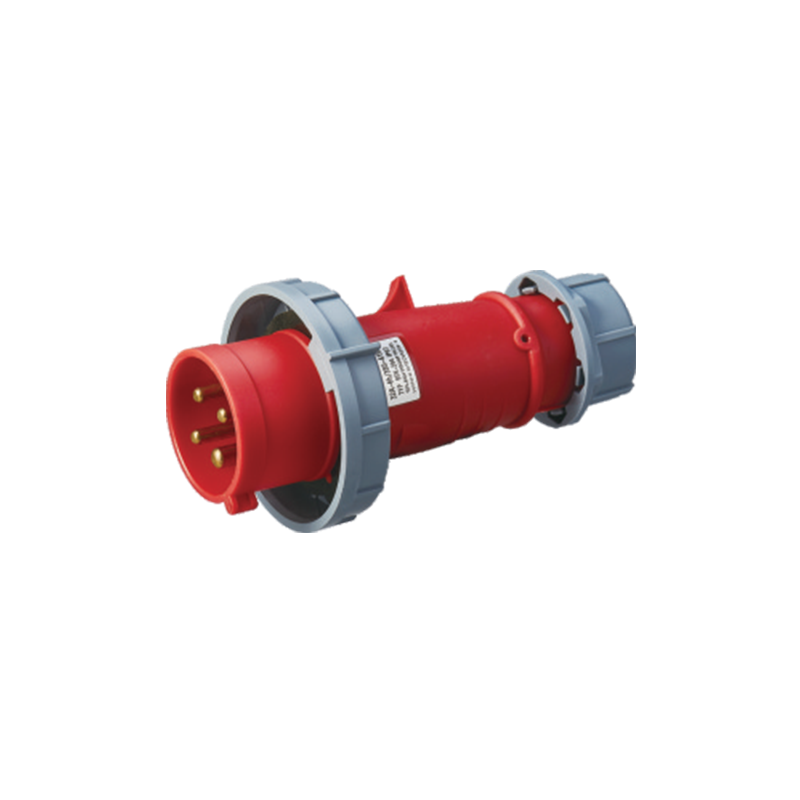

One critical aspect of plug design is the consideration of environmental factors. In industrial settings, where equipment may be exposed to harsh conditions, waterproof industrial sockets become essential. These sockets are specifically engineered to resist moisture, dust, and other contaminants that could compromise their integrity. By incorporating seals and robust materials, waterproof industrial sockets help ensure that electrical connections remain secure and functional, even in adverse conditions. This is particularly important in factories and outdoor sites where machinery is often exposed to rain, splashes, or cleaning processes.

Moreover, waterproof plugs and sockets are vital for outdoor applications. Many industries rely on outdoor power supply boxes that provide electricity to tools, machinery, and lighting fixtures in open environments. These boxes must be designed to withstand the elements, ensuring that electrical connections remain safe regardless of weather conditions. The design of outdoor power supply boxes typically includes features such as weather-resistant materials and secure locking mechanisms to prevent unauthorized access. Such design elements not only enhance safety but also improve the longevity of the equipment.

Additionally, the layout of the electrical contacts within plugs and sockets plays a significant role in safety. For instance, recessed or shielded contacts can prevent accidental contact with live electrical components, thereby reducing the risk of electric shock. This is especially relevant in environments where multiple users may interact with electrical equipment, such as construction sites or public areas.

Another important consideration in plug design is the need for standardized configurations. Standardization helps reduce confusion and potential misuse of plugs and sockets. By adhering to established standards, manufacturers can ensure compatibility across different devices and prevent dangerous connections. For example, using a universal design for outdoor power supply boxes facilitates easy access and enhances safety, as users are less likely to attempt connecting incompatible devices.

In addition to these design features, proper maintenance and inspection of plugs and sockets are crucial for ongoing safety. Regular checks can identify wear and tear, loose connections, or damage that could pose hazards. Implementing a routine maintenance schedule can significantly reduce the risk of electrical failures and enhance the overall safety of electrical systems.

The role of plug design in electrical safety cannot be overstated. With the integration of waterproof industrial sockets and outdoor power supply boxes, manufacturers can create solutions that address the unique challenges posed by different environments. By prioritizing robust design, companies not only ensure compliance with safety regulations but also contribute to a safer operational environment for all users.

In conclusion, the design of plugs and sockets is a critical component of electrical safety. Through features that enhance durability, usability, and environmental resistance, manufacturers can less risks associated with electrical connections. As technology continues to evolve, the importance of innovative and safe plug design will remain a focal point in the pursuit of improved electrical safety standards across various industries. By investing in thoughtful design, we can create a safer future, where electrical devices and systems operate efficiently without compromising the well-being of users.