Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

As homeowners and businesses look to enhance their outdoor spaces, waterproof electrical sockets have emerged as essential components, ensuring safety and functionality even in challenging weather conditions. This article explores the technology behind waterproof electrical sockets, focusing on their construction, the types of connectors used, and their applications in outdoor environments.

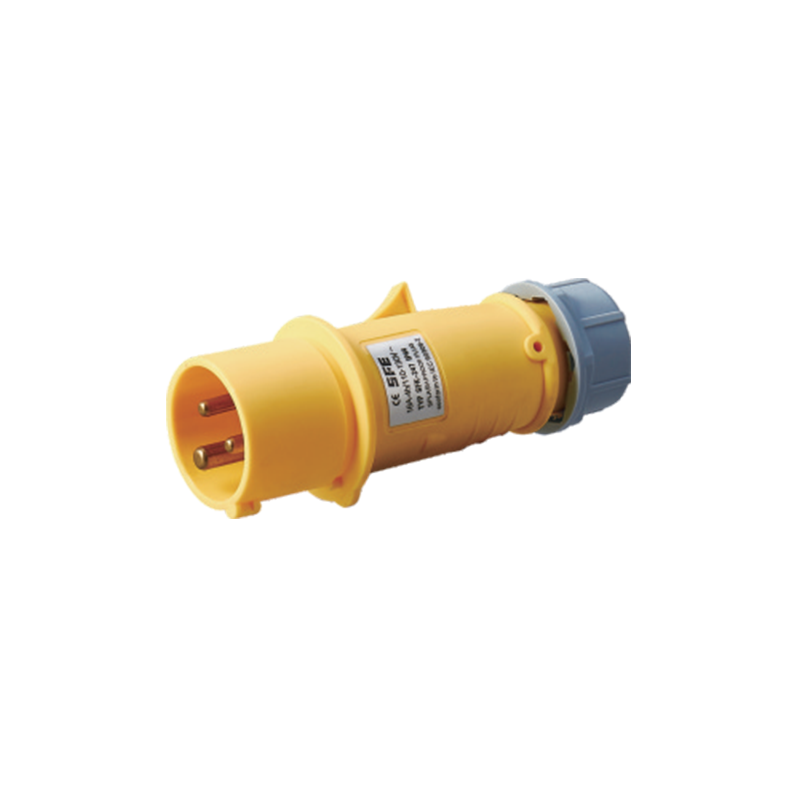

Waterproof electrical sockets are designed to withstand exposure to moisture, dust, and other environmental factors that can compromise electrical safety. These sockets are typically made from robust materials that resist corrosion and degradation caused by prolonged exposure to the elements. The housing is usually constructed from high-quality plastics or industrial metals, ensuring that the sockets remain functional over time. The key to their effectiveness lies in their design, which incorporates sealing mechanisms to prevent water ingress.

One of the more crucial aspects of waterproof sockets is the use of industrial metal plug sockets. These sockets are engineered to provide a strong and secure connection for various electrical appliances used outdoors. Unlike traditional plastic sockets, industrial metal plug sockets offer enhanced durability and resistance to physical damage. Their robust construction ensures they can handle the demands of outdoor environments, where conditions can be unpredictable.

In addition to industrial metal plug sockets, high current quick connectors play a significant role in outdoor electrical setups. These connectors are designed for applications requiring substantial power transfer while maintaining a safe and secure connection. High current quick connectors facilitate rapid assembly and disassembly, making them ideal for temporary setups, such as outdoor events or construction sites. Their waterproof design ensures that even during heavy rain or exposure to water, the connection remains intact, preventing electrical failures that could pose safety risks.

The integration of direct current plugs into waterproof sockets further enhances their versatility. Direct current (DC) plugs are essential for applications that require low voltage, such as solar power systems and electric vehicle charging stations. By incorporating direct current plugs into waterproof electrical sockets, users can safely connect their devices without worrying about water damage. This feature is particularly valuable in outdoor settings, where traditional AC connections might not be suitable or safe.

The construction of waterproof electrical sockets involves several critical components. one, the internal wiring must be protected from moisture. This is typically achieved through the use of rubber grommets and sealing compounds that prevent water from seeping into the socket. Additionally, the electrical contacts within the socket are often plated with materials that resist corrosion, ensuring a reliable connection over time.

Another essential feature of waterproof sockets is their ease of use. Many models are equipped with spring-loaded covers that automatically seal the socket when not in use. This design less the risk of water ingress when the socket is unoccupied, providing peace of mind for users. Furthermore, these covers can often be opened with one hand, making it convenient for users who may be handling tools or equipment at the same time.

In outdoor settings, waterproof electrical sockets find applications in various areas. They are commonly used in gardens, patios, and balconies, providing power for outdoor lighting, fountains, and electrical tools. In commercial settings, these sockets are crucial for powering equipment used in landscaping, maintenance, and outdoor events. Additionally, waterproof sockets are essential in marine environments, where boats and docks require reliable electrical connections that can withstand harsh conditions.

Safety is a primary concern when dealing with electrical installations, especially outdoors. Waterproof electrical sockets are designed with safety features that lessen the risk of electrical shocks and short circuits. The use of high current quick connectors, for instance, allows for secure connections that prevent accidental disconnections, which can advance to exposed wires. Similarly, the robust construction of industrial metal plug sockets ensures they can withstand the rigors of outdoor use without compromising safety.

As the demand for outdoor electrical solutions continues to grow, the technology behind waterproof electrical sockets is evolving. Manufacturers are continually innovating, incorporating advanced materials and designs to enhance performance. This includes developing sockets that can handle higher power loads and integrating smart technology for remote monitoring and control.

In conclusion, waterproof electrical sockets are essential components for anyone looking to enhance outdoor spaces safely and effectively. Their design, featuring industrial metal plug sockets, high current quick connectors, and direct current plugs, makes them versatile and reliable for various applications. With ongoing advancements in technology, these sockets will continue to play a crucial role in ensuring safe and functional outdoor electrical systems, catering to the diverse needs of homeowners and businesses alike. By prioritizing safety and durability, waterproof electrical sockets provide peace of mind in all weather conditions, ensuring that outdoor electrical connections remain reliable and secure.