Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

Maintaining industrial power outlets is essential for ensuring safety and efficiency in any workplace. Industrial environments often have high demands on their electrical systems, making regular maintenance not just beneficial but necessary. This article explores the ideal practices for maintaining industrial power outlets, focusing on the importance of using quality industrial electrical spare parts and ensuring that electrical box plugs are in good condition.

Understanding Industrial Power Outlets

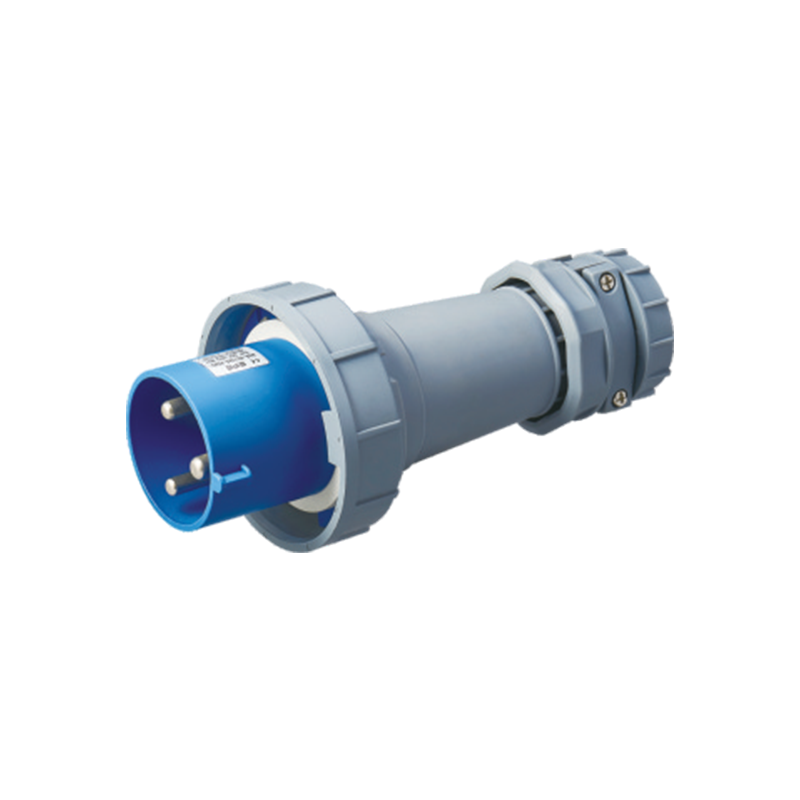

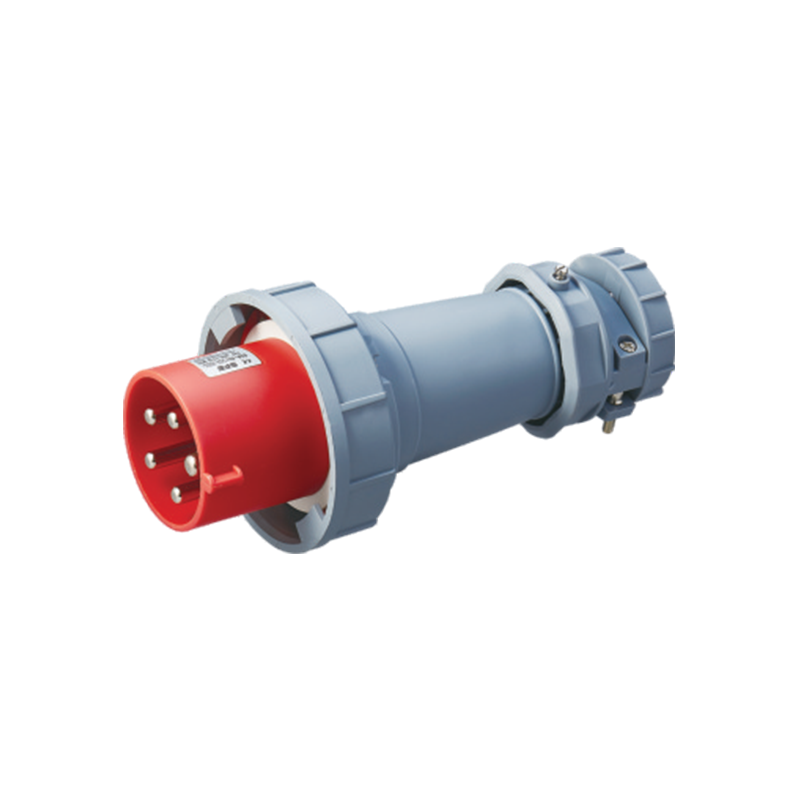

Industrial power outlets are specifically designed to handle heavy loads and provide reliable power to various equipment and machinery. They come in various configurations, including different voltages and amperages, to suit specific industrial applications. Given the complexity and critical nature of these systems, any malfunction can advance to significant downtime and safety hazards.

The Importance of Regular Inspections

One of the more critical aspects of maintaining industrial power outlets is conducting regular inspections. Routine checks help identify potential issues before they escalate into more significant problems. During an inspection, look for signs of wear and tear, such as frayed wires, loose connections, or discoloration around the outlets.

Inspect the electrical box plug for any damage. If the plug appears cracked or worn, it may not create a secure connection, pilot to power interruptions, or safety risks. It's advisable to replace any damaged components promptly to avoid further complications.

Cleaning and Dust Control

Industrial environments can accumulate dust, debris, and contaminants, which can adversely affect electrical outlets. Regular cleaning is essential for preventing dirt from interfering with the connections. Use a dry cloth or a vacuum cleaner with a brush attachment to remove dust from around the outlets and plugs.

For deeper cleaning, ensure that the power is turned off before using any cleaning solutions or solvents. Always follow manufacturer guidelines for cleaning materials to avoid damaging the outlets or electrical components.

Checking and Replacing Electrical Box Plugs

Electrical box plugs are integral to the functionality of industrial power outlets. These plugs connect equipment to the electrical supply and must be in good condition to ensure proper operation. During maintenance, check that the plugs fit snugly into the outlets. Loose connections can advance to overheating and potential fire hazards.

If you notice any signs of wear, such as discoloration or physical damage to the plug, replace it immediately. Using quality industrial electrical spare parts for replacements ensures reliability and longevity, reducing the need for frequent replacements.

Addressing Overloading Issues

Overloading is a common issue in industrial settings. It's crucial to ensure that the outlets are not being asked to support more power than they are designed for. Regularly assess the power needs of your equipment and compare them against the ratings of the outlets in use.

If you find that certain outlets are consistently overloaded, consider redistributing the electrical load across multiple outlets or upgrading to outlets with higher capacity. This not only prolongs the lifespan of the outlets but also reduces the risk of electrical fires.

Ensuring Grounding and Bonding

Proper grounding and bonding of industrial power outlets are vital for safety. Grounding helps protect personnel from electrical shocks, while bonding prevents differences in voltage between conductive surfaces. Regularly inspect grounding connections to ensure they are secure and free from corrosion.

If any grounding issues are identified, they should be addressed immediately. Engaging a qualified electrician for these tasks is advisable to ensure compliance with local electrical codes and standards.

Utilizing Quality Industrial Electrical Spare Parts

The use of high-quality industrial electrical spare parts is crucial for maintenance and repairs. Substandard components can advance to inefficiencies, increased wear on equipment, and potential safety hazards. When sourcing replacement parts, prioritize reliability and compatibility with your existing electrical systems.

Always keep an inventory of critical spare parts on hand for less downtime in case of unexpected failures. This proactive approach ensures that any maintenance or repairs can be carried out promptly and efficiently.

Training Staff on Electrical Safety

A significant aspect of maintaining industrial power outlets involves educating staff on electrical safety practices. Employees should be aware of the signs of faulty outlets, such as unusual sounds or smells, and understand the importance of reporting these issues immediately.

Conducting regular training sessions on electrical safety can foster a culture of awareness and responsibility among employees, ultimately piloting a safer workplace environment.

Maintaining industrial power outlets is a crucial task that requires attention to detail and regular oversight. By implementing ideal practices such as routine inspections, cleaning, and using quality industrial electrical spare parts, you can ensure the longevity and safety of your electrical systems. Remember, proper maintenance not only protects equipment but also safeguards the well-being of all personnel working in industrial settings. Prioritizing electrical safety and maintenance will advance more efficient operations and reduce the risk of electrical hazards.